Hey

it's been a while! I've had a lot more time to work on the robot

recently, so I've been making so much progress that I haven't been able

to write it all down.

Last

time I left off, I was having problems getting the robot to respond

quickly over serial communication. It turns out that the 10 AA batteries

that I was using as my main power source were draining to quickly.

I decided to fix the issue by finally getting a lipo battery. I chose a 3 cell battery, which is rated at 11.1V.

Lipo

batteries are dangerous and should not be discharged below a certain

rate. With the addition of the kinect I also realized that I need

something that would provide a stable 12V. I'm sure the kinect has an

internal voltage regulator, but I still want to be able to provide a

steady voltage. This would also make sure the motors are operating at

their rated voltage.

In

order to solve the problems above I bought a buck-boost converter and a

low voltage cut-off circuit. The battery came with really large wires

so I also had to buy an xt60 connector. I'm also going to add a more

robust power switch. Eventually the circuit will look like this

Battery >> connector >> power switch >> low voltage protection circuit >> buck boost converter.

Currently I just have the low voltage protection circuit in there with the connector and the switch.

Since

cost is a driving factor for me, I chose the cheapest low voltage

protection circuit I could find, which relied on a potentiometer to

adjust the cut offs. This proved to be really annoying to set and very

unreliable. In the future I'm going to pick something that provides me

with more information even if it costs extra.

Because

I don't have a power supply, I had to put some resistors between the

battery and the circuit, measure the output with my voltmeter and then

twist the adjustment screw on the potentiometer. The process was

excruciating, but I did manage to set the cutoff point at about 11 V.

Now that I have a few extra pieces of gear it's time to start thinking

how I'm going to fit all of that on the robot.

Enclosure:

In

the past I made a second platform for the robot and elevated it with

columns. Going forward I wanted to make the robot more presentable and

take advantage of the space more. I plan to put the kinect and lidar on

the second level, so I needed another approach.

Here are the objectives of the enclosure

- Make the robot look more professional

- Hold the lipo battery securely

- Provide space for the low voltage circuit

- Provide space for the buck boost converter

- House the arduino and the motor shield

- House the raspberry pi

- House the raspberry pi battery

- Provide access to the raspberry pi battery power button

- Provide access to the arduino usb port

- Mount at least 4 ultra sound distance senors

- Provide room on the second level for the kinect and lidar.

As

you can see it's a tall order. When I added the adafruit motor shield I

had to screw down the arduino. The existing holes in the enclosure

weren't easy to line up against. As a result the board is positioned in

such a way that when you plug the USB cable in, it sticks out past the

edges of the platform. This isn't ideal as I hoped the whole thing could

be completely enclosed. However this was actually convenient for

development, because I could access the cable from the side.

The

enclosure took me more iterations that I would have liked. My biggest

issue was lining up holes in the 3d model with holes on the actual

chassis, since the chassis is from china, I didn't get a drawing of

where the holes were and had to rely on my imperfect measurements made

with a caliper.

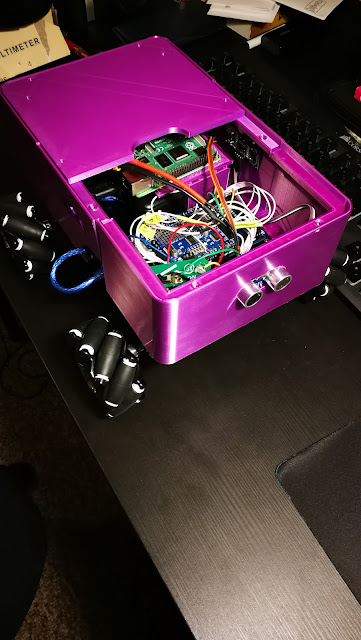

But eventually I was able to print the enclosure! Here is what the end product looks like!

I

had to create a cut out for the arduino cable and profile cutouts for

the distance sensors. The lipo battery is fixed with a ushaped bracket,

same with the raspberry pi battery. The pi is mounted on a plate that

inserts into the battery bracket. This enables it to be removed if need

be.

I also had to get a usb-C cable with a 90-degree bend so that it wouldn't interfere with the lipo battery.

Overall, it fits really nice!

To

attach the roof of the enclosure to the walls, I added a lip to the

walls. The lips houses a nut inserted into a cutout. This nut allows the

roof to the secured with screws. The roof also has a large opening in

the middle to feed wires through from future additions such as the lidar

or the kinect.

Another

part of this issue was getting the enclosure to print in a way that

would look beatiful. Since the walls are mostly flat it made sense to

lay them down, in the print configuration, but that resulted in some

ugly layers. What I ended up doing instead is printing all the pieces

upright. This took wayy more time, but the result was phenomenal! I

originally intended for the enclosure to be a mint colour, but I ran out

and had to use purple silk PLA. This gives the robot a distinct shine!

Overall, I'm really happy with the progress so far. All of the wire mess can be hidden now and protected from my cats.

PID:

After

making the enclosure I started driving the robot around again, and I

was disappointed with the accuracy of the control. I drove the robot

forward and the told it to stop. The robot overcorrected by driving

backwards. This told me that there is still work that needs to be done

on the PID tuning.

This

stuff is the bane of my existence. I realized I may be a bit out of my

depth as I've previously tried a lot of different tuning approaches, and

I still couldn't get a reliable result. I decided to find a PID library

and found the Arduino PID library by Brett.

This

library is intended to replicate what is being used in industry and has

numerous improvements over the regular PID algorithm. I replaced my

code with the PID from the library and was still having trouble.

The

first thing that I did right was to correct the low pass filter I was

using on my velocity measurements. As they say garbage in garbage out. I

adjusted the cut off frequency and the sampling rate of the filter,

which provided significantly more accurate results. That got me thinking

that I also had to do the same for the PID controller. One of the

improvements that the library implements is that the controller runs at a

set interval to increase the performance. After playing around with the

PID constants I was finally able to get the controller to follow a sine

wave!

I

was excited to try it with the rest of the code, however when I tried

to setup the serial node on the pi to connect to the arduino I got the

error

wrong checksum or topic id

I

looked online and one of the solutions is to increase the delay in the

arduino loop. Yesterday I was able to fix this problem by increasing the

time between evaluations of the PID loop. I think it has some

interrupts in there that must be screwing up my message reception. I

still get the error occasionally, but at least it's able to connect.

I

tried to drive the robot around, but there were HUGE spikes in output!

The thing will lurch forward like a monster that is out for blood! This

is disappointing, because I'm not worse than when I started in terms of

PID control. The PID library that I'm using wasn't designed for robots,

but rather fridges or cruise control in a car. So, I'm going to

investigate if there's something I can do to get smoother performance.

The library offers quite a few sophisticated tools that I can take

advantage of, such as adjusting constants on the fly.

If I can't figure it out, I might try another library or just go back to my code.

Here's a video of the robot startling my cat:

https://www.youtube.com/shorts/RhPg2kjIFW0